OEM Manufacturing

Manufacturing - custom-made production - contract manufacturing

Since the foundation in 1978 Bioanalytic GmbH supplies companies as original equipment manufacturer (OEM) who appreciate our good service and highest quality. These include many well-known companies from the fields of diagnostics, analytics, life science and industrial metrology.

Bioanalytic GmbH offers individual solutions and produces OEM reagents from single containers to complete kits with your company logo (commissioned production). In cooperation with you we develop a product which will come up to your personal requirements and support you with our scientific expertise, technical support and our long standing experience.

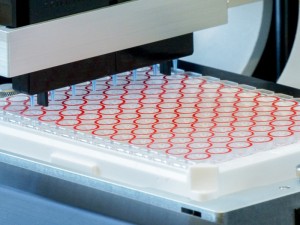

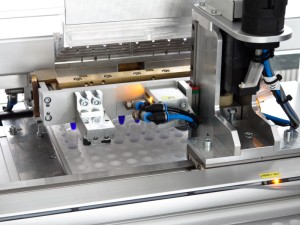

Bioanalytic GmbH offers customized manufacturing capabilities - from simple filling service to the manufacturing of sophisticated products with unique specifications. Our flexibility allows us to make the products and processes according to individual customer requests. With our modern fully and semi-automated systems we fill containers precisely with high-quality reagents. Strict quality standards and high demands on the production conditions ensure the high quality of your products. Certificates of Analysis (CoA) are provided via the platform LotDocs and retrieved at any time. In addition we create safety data sheets (SDS) and provide them on the platform SDS-ID International which is compliance to the law across the entire trading chain is garanteed.

Bioanalytic GmbH is certified for manufacturing reagents for the use in in vitro diagnostic (IVD) according to EN ISO 13485 and has a certified quality management system according to EN ISO 9001. All products are manufactured reproducibly to a high standard and are verified by all necessary quality controls.

Our goal is to establish long-term B2B partnerships by providing high quality, customized products with just-in-time delivery solutions based on a robust quality system and materials management.

We welcome OEM inquiries from diagnostic and analytical customers as well as life science and chemical industries for OEM reagents and services.

Contract Manufacturing of Bottles and Kits

With modern fully and semi-automated manufacturing facilities we produce your customized reagents in different container and volumes.

We offer you

- Manufacturing and filling of reagents in different container from microliters up to liters (e. g. plastic, glas and dripping bottles, vials, screw cap vessels, ...)

- Filling of glas ampoules (e. g. calibration standards)

- Filling of Aluminium laminated pouches (sachets)

- Manufacturing of ELISA kits and antibody coatings in 96- and 384 microtiter formate

- Sterile filling of solutions by laminar flow system (cleanroom class A) e. g. in clear-sightedly PET bottles including tamper-proof seal

- Filling of small series with very low volumes

- Customized manufacturing of kits with individual requirements

- Printing of labels and instructions for use with your company logo and address

- Generation and printing of barcodes on product labels (e. g. GS1, HIBC, ...) for automated data acquisition of your products by using UDI and fulfilling the FDA requirements for GUDID

- Packaging (labeling, packing) of individual packages or kits

- Integrated quality control of all reagents and labels

- Certificate of Analysis and Quality (CoA)

- Safety data sheet with your customer contact details and logo in many country and language versions and SDS-ID

- Packaging for shipping, shipping service

Ampoules and Vials

With modern fully and semi-automated manufacturing facilities we fill glass ampoules, vials with different volumes according to customer specifications

We offer you

- Production of reagents (e.g. calibration standards) and filling in clear glass or amber glass One-Point-Cut (OPC) ampoules or vials (injection vials, rimmed vials, screw thread vials) of different sizes

- Filling of small series with very low volumes

- Packaging (labeling, packing) of individual packages or kits

- Customized manufacturing of kits with individual requirements

- Printing of labels and instructions for use with your company logo and address

- Integrated quality control of all reagents and labels

- Certificate of Analysis and Quality (CoA)

- Safety data sheet with your customer contact details and logo in many country and language versions and SDS-ID

- Packaging for shipping, shipping service

Sachets

We fill sachets (aluminium composite bags) with different volumes according to customer specifications

We offer you

- Production of reagents and filling into sachets (aluminium composite bags) of various sizes

- Filling of small series with very low volumes

- Packaging (labeling, packing) of individual packages or kits

- Customized manufacturing of kits with individual requirements

- Printing of labels and instructions for use with your company logo and address

- Integrated quality control of all reagents and labels

- Certificate of Analysis and Quality (CoA)

- Safety data sheet with your customer contact details and logo in many country and language versions and SDS-ID

- Packaging for shipping, shipping service

Reaction Tubes

With modern fully and semi-automated manufacturing facilities we fill e.g. original Eppendorf Safe-Lock reaction tubes with your specific reagents.

We offer you

- Manufacturing of reagents to specific formulations (optional)

- Degassing of reagents for a high filling accuracy

- Automatic filling of your reagent

- Filling of different reagents and/or volumes simultaneously per series/package

- Automatic sorting of the tubes in Styrofoam boxes to max. 100 pieces per pack. (also lower quantities or multi-packs are possible)

- Styrofoam box serves as a tube rack for manual use or as donors for further automated processing

- Additional packaging, package inserts, labeling, shipping service, etc.

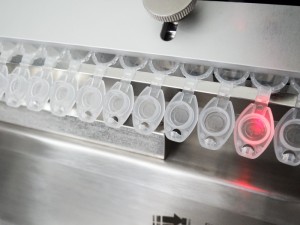

Barcodes on your Product Label

Barcodes are becoming increasingly important in today's digital networking and allow fully automatic identification of products.

Manufacturers and users benefit from the improved traceability provided by batch-dependent barcodes and automated data acquisition in warehouse management. In addition, barcodes can provide increased security by identifying the reagents. Reagents can thus be used in your instruments without any mix-ups.

We support you in the implementation of your requirements and generate standardized data structures such as GS1 (GTIN/EAN) or HIBC (medical devices) in different code versions (Code128, DataMatrix). Individual data structures in different versions as 1D barcodes and 2D codes (matrix codes) are also possible. With this code as UDI, you fulfill the FDA requirements for GUDID.

If you have special requirements, please contact us.